Across the globe, businesses face the challenge of shipping goods from one place to another on a daily basis. They encountered many common questions when shipping goods, such as: How to transport goods (by truck, ship, train, or airplane)? How to meet delivery deadlines? How to keep transporting goods cost-effective?

The solution to these problems is to optimize shipments through advanced simulation techniques. These techniques allow businesses to identify shipments with similar routes, combine them, and eliminate significant costs.

Vehicle Scheduling and Routing (VSR) Optimization provided by SAP Transportation Management (TM) is a powerful tool designed to streamline these processes. By assigning freight units to available capacities, VSR Optimization helps logistics managers/planners determine the most efficient delivery sequences and transportation schedules while adhering to various constraints.

The Core Objective of VSR Optimization

The primary goal of VSR Optimization is to allocate freight units to vehicle capacities in a manner that minimizes costs while considering a multitude of multiple logistical constraints. These constraints include vehicle capacities, delivery windows, and route restrictions to specific customer requirements. VSR Optimization doesn’t just plan routes; it also optimizes the sequence of deliveries and the timing of transportation activities, ensuring that the entire logistics process is as efficient as possible.

Prerequisites for Implementing VSR Optimization in SAP TM

Before diving into VSR Optimization, it’s essential to set up the necessary master data and system configurations. Here’s a checklist to get started:

1. Master Data Configuration: Define network connections to the optimization server and specify the maximum number of users. This setup is crucial for ensuring that the optimization process runs smoothly and efficiently.

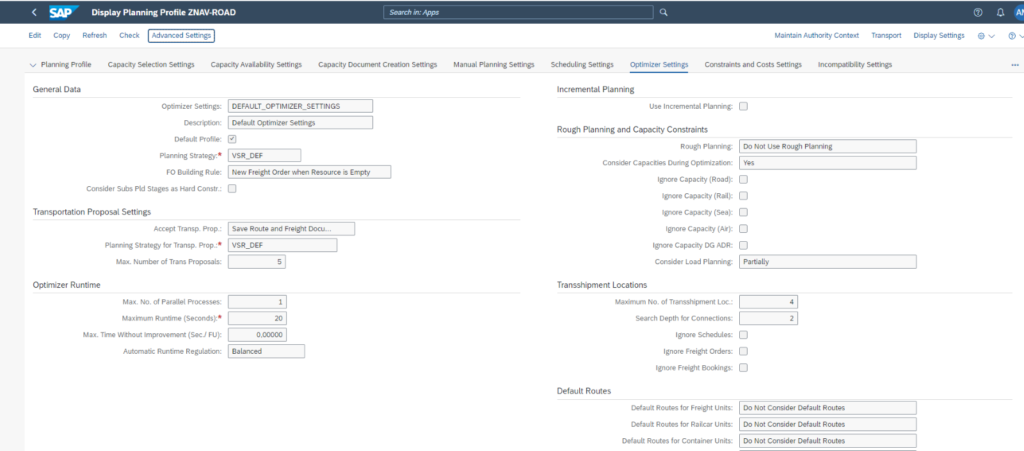

2. Planning Profile: Create and configure a planning profile. This profile should include:

- Optimizer Settings: Specify the planning strategy, which dictates how the system will approach optimization.

- Constraints and Costs Settings: Define the cost parameters and constraints that the optimizer must consider.

- Capacity Selection Settings: Configure settings for selecting the appropriate capacities for each freight unit.

3. Transportation Lanes and Locations: Define transportation lanes and, for multimodal transport, set up transshipment locations or default routes.

4. Business Add-Ins (BAdIs): If you need to customize the input or output of the VSR Optimization process, configure the relevant BAdIs for preprocessing and postprocessing.

How VSR Optimization Works in SAP Transportation Management

VSR Optimization generates a transportation plan by processing freight orders and capacities. It starts with the existing freight orders, either from a previous optimization run or from manual planning, and incrementally inserts freight units into the transportation plan. The optimizer then iterates through various configurations, attempting to minimize total costs while respecting the predefined constraints.

At the end of the process, the optimizer delivers the best possible solution. This solution might include decisions such as not delivering a freight unit if the cost of delivery exceeds the penalty for non-delivery. In the end, the key to successful VSR Optimization lies in balancing the size of freight units. Creating extremely large or small freight units can complicate the planning process, so finding a middle ground is recommended.

Example Scenario: Imagine you have a truck with a 20-ton capacity and you need to transport flour. You could create a single 20-ton freight unit or break it down into 20,000 1-kilogram units. Neither approach is ideal. The former oversimplifies the process, while the latter creates unnecessary complexity. A balanced approach would involve creating several medium-sized freight units that are manageable yet optimize space and cost.

Enhancing VSR Optimization with Additional Features

VSR Optimization also allows for the generation of multiple transportation proposals for each freight unit. This feature enables logistics managers to evaluate different plans and choose the most suitable one.

SAP offers two standard planning strategies for VSR Optimization: VSR_DEF and VSR_1STEP. The VSR_1STEP strategy is particularly useful if you want the system to perform carrier selection immediately after the optimization process, streamlining the entire workflow.

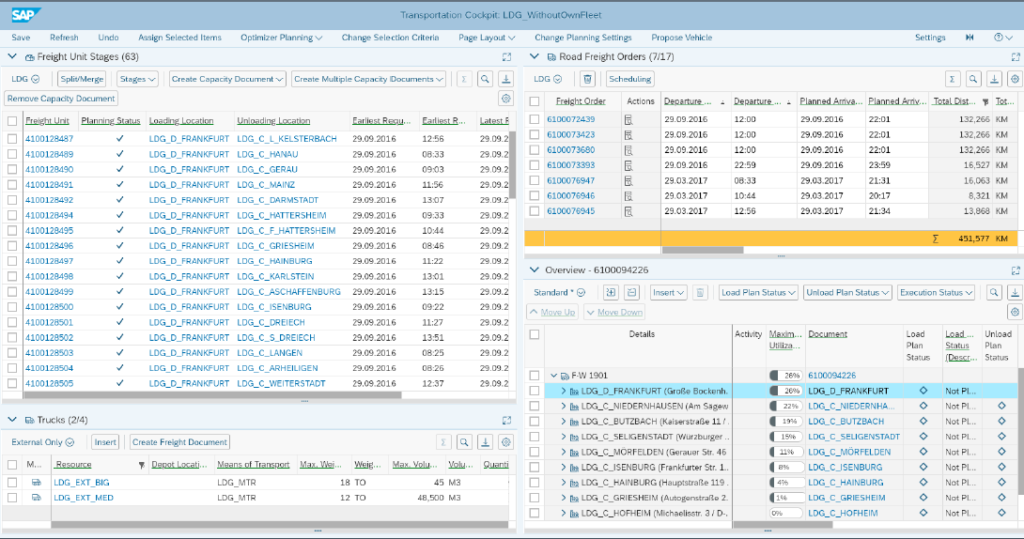

Executing VSR Optimization

To initiate VSR Optimization, logistics managers can use the Optimizer Planning function in the transportation cockpit. There are several options available:

- Optimize All Entries: Perform VSR Optimization for all relevant entries.

- Optimize Selected Entries: Focus on specific entries while considering all capacities.

- Background Optimization: Run the optimization process in the background, which is especially useful for large datasets or complex planning scenarios.